Efficiency and sustainability with HT Plus

Efficiency

and sustainability with

HT Plus.

Increase.

HT Plus systems optimize your waterjet cutting system.

The “plus” stands for the decisive advantages

conventional peripheral devices of a waterjet cutting system,

because the water quality and the quality of the installed components are essentially responsible for the service life of the system:

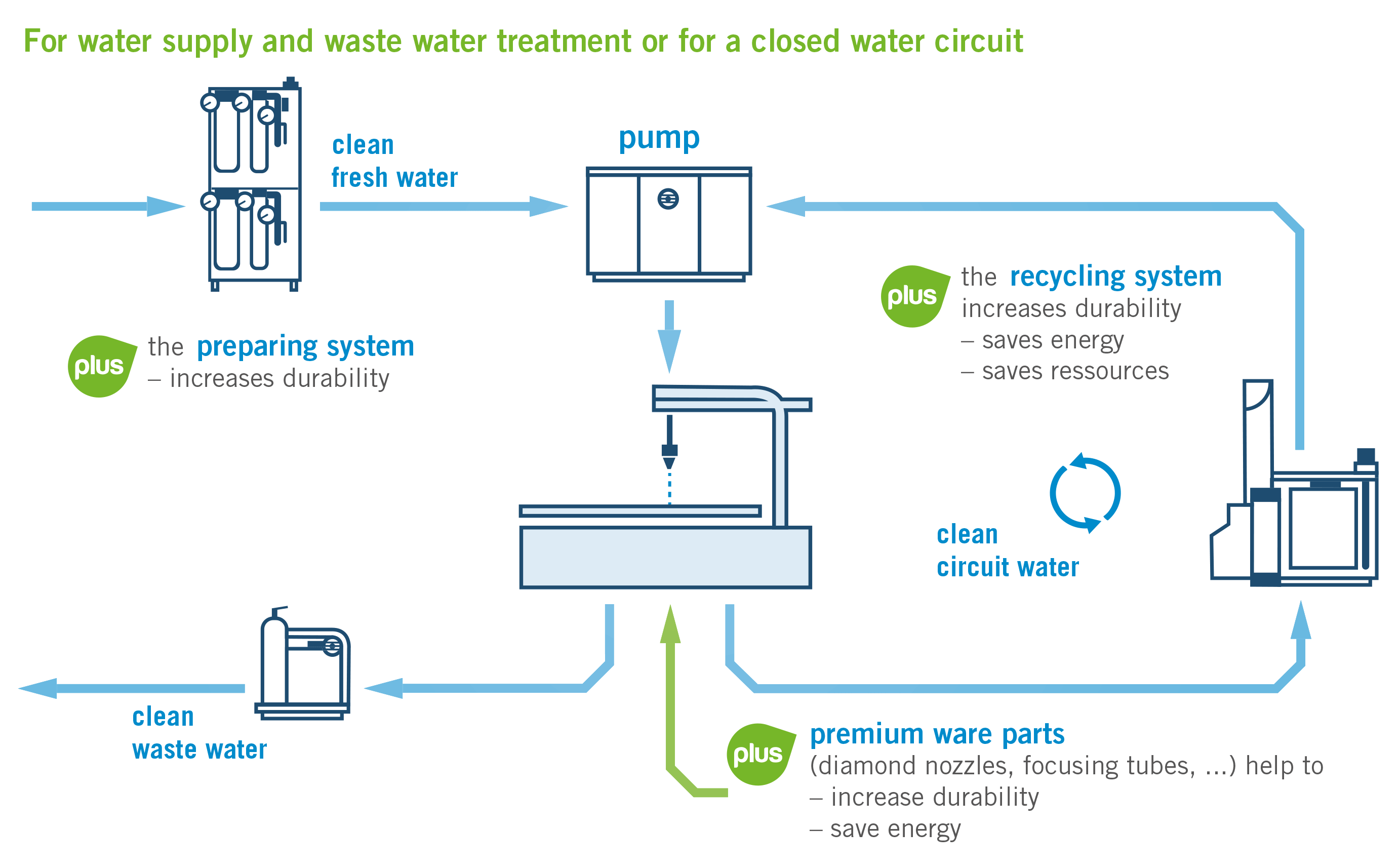

- The PREPARING SYSTEM HT PR-EVO2 improves the quality of the water.

- With the RECYCLING SYSTEM HT RS the used cutting water can be cleaned and reused in the cycle.

- The HT Plus premium wear parts contribute to the trouble-free operation of the system, thanks to their high quality.

- The Highpressure pump HT SERVO-JET4000 significantly reduces energy consumption with its unique direct servo drive technology.

- HT HT Plus products are developed according to strict criteria and help to increase system service life, save energy and conserve resources.

- Hapro Technik is a leader in technolog.

- Efficiency and sustainability with a focus on the environment are very important.

Ideal water quality for high-pressure pumps. Whether or not a high-pressure pump performs well depends to a large degree on the water quality after water treatment. Instead of costly technology, our Preparing System HT PR-EVO2 optimizes all factors which reduce downtimes relating to water quality with intelligent and effective materials –without chemical additives. With the Preparing System HT PR-EVO2, the maintenance intervals can be

extended, which results in considerable cost savings.

At the same time, operational safety is increased by reducing damage to the high-pressure pump due to water-side malfunctions. This results in quick

amortisation with moderate consumption costs.

Wasser Rrecycling with the Recycling System HT RS

Save fresh water, wastewater costs and any regulatory inspections, by reusing your cutting water in the cycle. In addition, the HT RS system optimizes the cutting water and thus extends the service life of your system.

Generally speaking, water jetcutting is an environmentally friendly technology.

However, given that a single cutting head uses on average 400,000 litres per year, large amounts of drinking water are needed. Once used, the water drains into the sewer which leads to considerable expenses. In many cases, these expenses involve disposal costs to remove traces of problematic materials left in the water after cutting.

For the HT Team it is important to keep the ecological footprint as small as possible. In the HT RS system (Hapro Technik Recycling System), the cutting water is processed without any chemical additives and fed via an intermediate

container back to the high-pressure pump. This saves water, makes it easier

to obtain an operating permit, protects the environment, and is less costly.

The maintenance costs and energy consumption are low.

For Exacting Requirements.

High-quality wear parts and consumables provide peace of mind when it comes to workpiece quality and machine availability.

Increase the productivity of your machine and, at the same time, reduce your

running costs with HT Plus Premium Wear Parts.

The Probably Most Energy-saving High-Pressure Pump in the World.

The HT Servo-Jet4000 clearly demonstrates the highest level

of efficiency with its exceptional energy efficiency and

simultaneous high cutting speed. Compared to a conventional high-pressure pump, the HT Servo-Jet4000 foregoes ineffective hydraulic systems. A plunger pump with three pistons coupled with a highly efficient Servo direct-drive boosts the overall efficiency to almost 98 %.